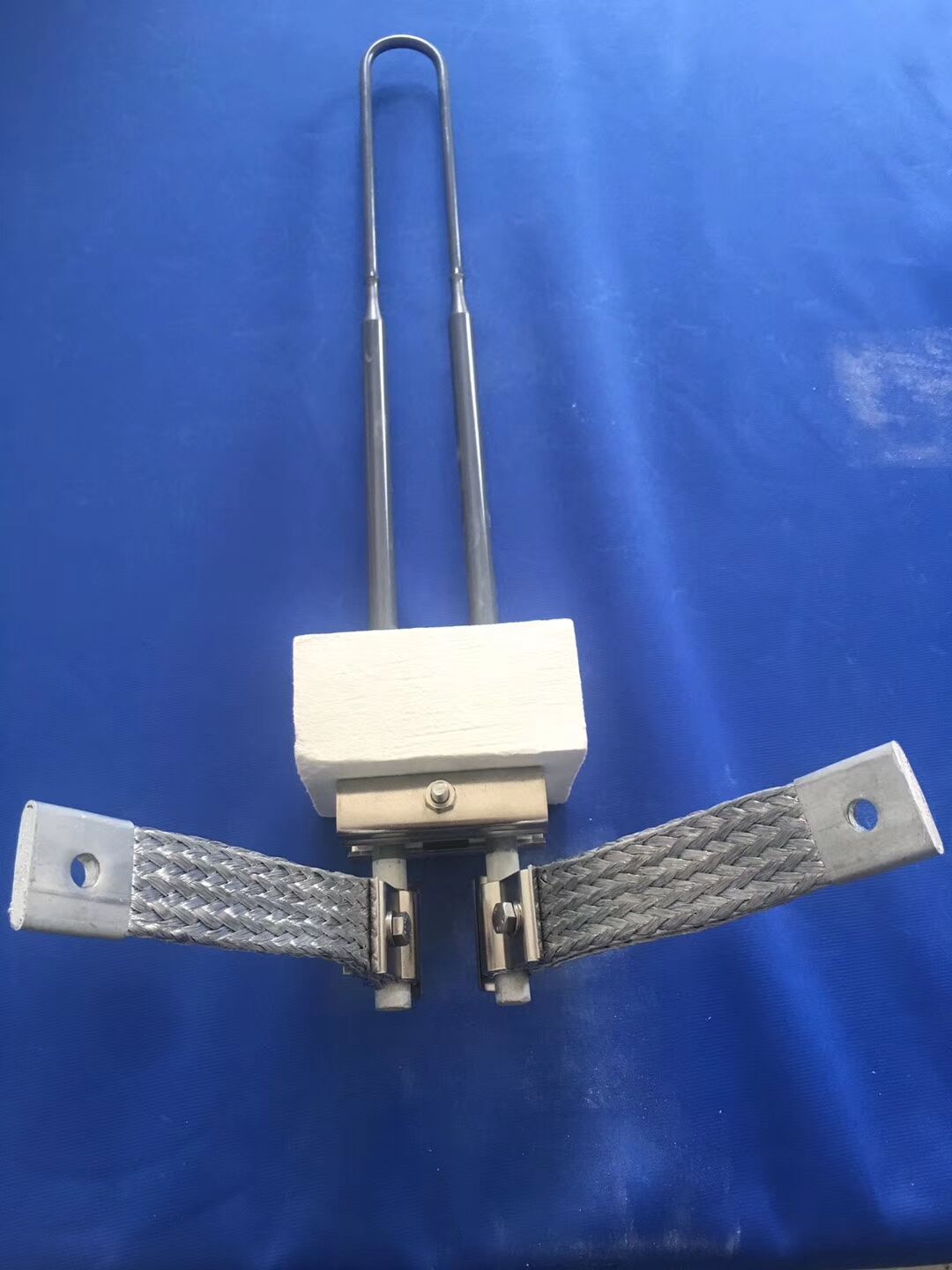

Factory Wholesale 1700/1800.C MoSi2 Heating Element

Mosi2 heating elements is a kind of resistance heating element basically made of high pure Molybdenum Disilicide. In oxidizing atmosphere, a layer of compact quartz protective film is formed on the surface of MoSi2 element owing to the high temperature combustion, which prevent MoSi2 from continuously oxidizing. In oxidizing atmosphere, its Max temperature can reach 1800.C, and its applicable temperature is 700-1700.C(can’t be used in 400-700.C for a long time, otherwise, it will be powdered and damaged due to strong oxidizing action in low temperature).

It can be widely used in such applications as heating elements of sintering and heat treatment of ceramics, magnet, glass, metallurgy, refractory,etc.